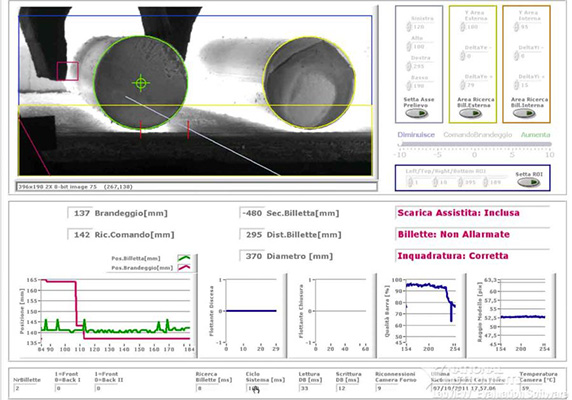

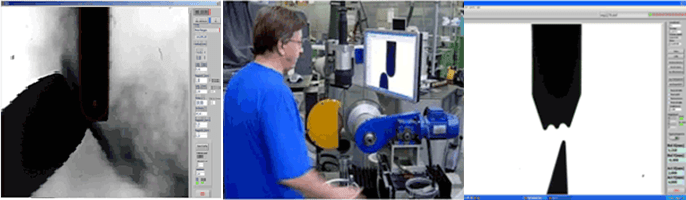

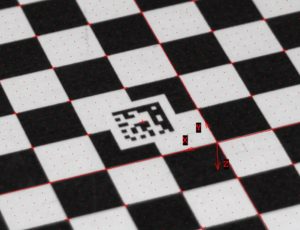

Optical Dimensional Control metrology is always based on the construction of contours extracted by Edge Detection algorithms.

Imagina srl algorithms can be configured to obtain the best accuracy and the best morphological/geometrical fitting.

Telecentric lens are special lenses which have constant magnification. This feature is especially useful when measuring:

- Length, distance, diameter of holes and depth of mechanical details

- Angle between segments

- Import/Export of geometrical information in dxf format