Principles Of Measurement

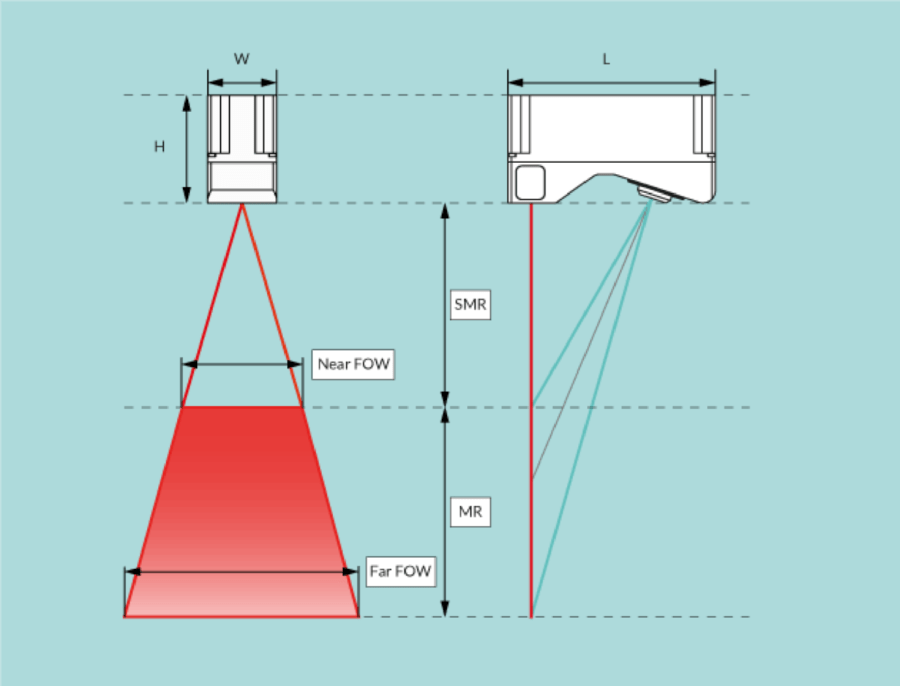

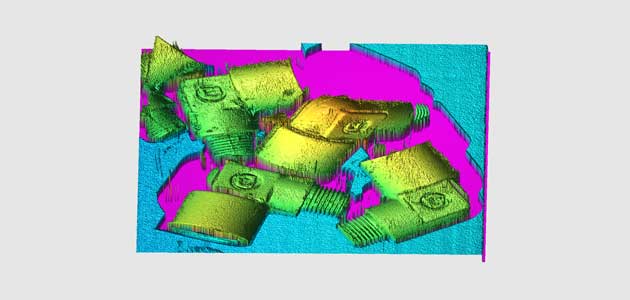

The working principle is that of triangulation. The system is composed of a laser plane and a camera.

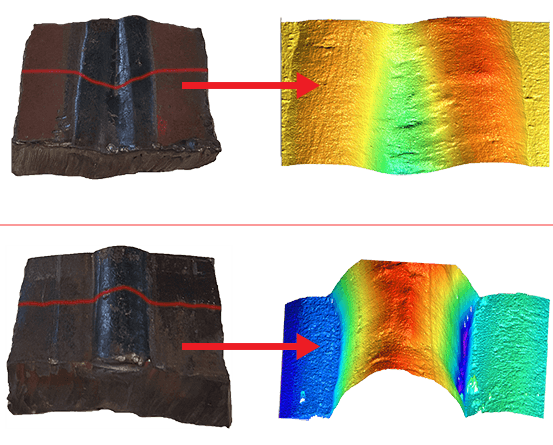

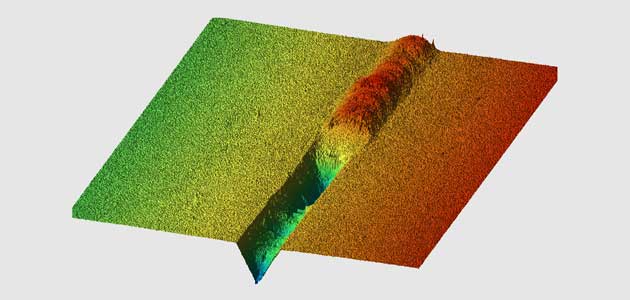

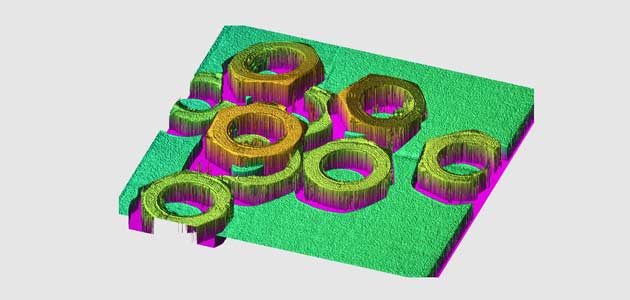

The laser ray produced by a diode is focused and transformed into a plane (also called sheet of light) that intercepts the target object. The target object diffuses, at least partially, the light which is collected by a particular kind of focalizing optic. The position of the sheet of light on the sensor allows for the reconstruction of the distance (Z) and position (X) of the target.